| GEOFLUIDS | |

| IMPERMIX® | |

| SLURRY CONSULT | |

| MUD DOCTOR | |

| PRODUCT LINE | |

| WHAT'S NEW | |

|

"Right Click" and "Save Target As" on each link below to download that section in PDF format. GEOFLUIDS IMPERMIX® SLURRY CONSULT MUD DOCTOR PRODUCT LINE |

|

All information on this website is property of and copyrighted by LIQUID EARTH SUPPORT, 2018. |

|

| IMPERMIX® |

HEAVY CONSTRUCTION >> Read More ENVIRONMENTAL REMEDIATION >> Read More TUNNELING >> Read More TRENCHLESS TECHNOLOGY >> Read More SPECIAL APPLICATIONS >> Read More  ENVIRONMENTAL REMEDIATION

ENVIRONMENTAL REMEDIATION

When hydraulic conductivity reaches as low as E-10 cm/sec and below, a practical limit is achieved in terms of testing laboratory capabilities. The great affinity of slag cement for water causes the cured slurry to continue hydrating while it is permeated. IMPERMIX® exhibits what we call a threshold hydraulic gradient below which no flow by advection will occur and the barrier becomes totally impermeable. Molecular diffusion is the only means of chemical transport through the barrier at this point and limit conditions then determine how much chemical may escape the containment. All things being equal, IMPERMIX®'s tortuosity is so complex that the coefficient of molecular diffusion to salt can be 10 to 50 times lower than of a typical clay liner or soil-bentonite slurry wall.

The conventional definition of porosity as per ASTM does not apply to self-hardening slurries,

in the same way as it does not apply to sodium silicate gel. You cannot define a wet material's physical properties

by destroying it by fire. Cured IMPERMIX® should be seen as a mineral gel of extremely low porosity in its natural

condition, hence its very low permeability. Since the actual "pore volume" is unknown, compatibility tests have to

be run differently:

Back to top. |

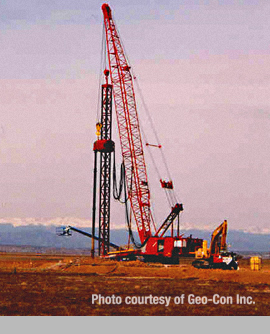

Barrier and cutoff walls: originally conceived for a one phase self-hardening slurry cutoff wall construction

method, IMPERMIX® because of its intrinsic properties of very low permeability and chemical compatibility with most

contaminants quickly served other techniques that can create barriers without trenching like deep soil mixing walls,

jet grouted barriers and vibrated beam thin walls.

Barrier and cutoff walls: originally conceived for a one phase self-hardening slurry cutoff wall construction

method, IMPERMIX® because of its intrinsic properties of very low permeability and chemical compatibility with most

contaminants quickly served other techniques that can create barriers without trenching like deep soil mixing walls,

jet grouted barriers and vibrated beam thin walls.